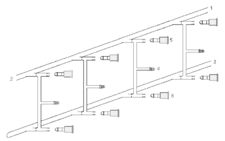

Schlenk line

The Schlenk line (also vacuum gas manifold), developed by Wilhelm Schlenk, is a dual manifold with several ports.[1] One manifold is connected to a source of purified inert gas, while the other is connected to a high vacuum pump. The inert gas line is vented through an oil bubbler, while solvent vapors and gaseous reaction products are prevented from contaminating the pump through a liquid nitrogen or dry ice/acetone cold trap. Special stopcocks or Teflon taps allow for vacuum or inert gas to be selected without the need for placing the sample on a separate line.

Schlenk lines are useful for safely and successfully manipulating air sensitive compounds. The high vacuum is also often used to remove the last traces of solvent from a sample. Vacuum gas manifolds often have many ports and lines, and with care it is possible for several reactions or operations to be run simultaneously.

Contents

Dangers

The main dangers associated with the use of a Schlenk line are the risks of an implosion or explosion. An implosion can occur due to the use of a high vacuum and flaws in the glass apparatus.

An explosion can occur due to the common use of liquid nitrogen in the cold trap, used to protect the vacuum pump from solvents. If a reasonable amount of air is allowed to enter the Schlenk line, liquid oxygen can condense into the cold trap as a pale blue liquid. An explosion may occur due to reaction of the liquid oxygen with any organic compounds also in the trap.

See also

- Glovebox - used to manipulate air-sensitive (oxygen- or moisture-sensitive) chemicals.

- Schlenk flask - reaction vessel for handling air-sensitive compounds.

- Perkin triangle - used for the distillation of air-sensitive compounds.

References

- ↑ Craig M. Davis and Kelly A. Curran (November 2007). "Manipulation of a Schlenk Line: Preparation of Tetrahydrofuran Complexes of Transition-Metal Chlorides". Journal of Chemical Education 84 (11): 1822-3.

External links

- Rob Toreki (25 May 04). Schlenk Lines and Vacuum Lines. The Glassware Gallery. Interactive Learning Paradigms Incorporated.

- Jürgen Heck. The Integrated Synthesis Course: Schlenk Technique (reprint at Norwegian University of Science and Technology). University of Hamburg.

- Handling and Storage of Air-Sensitive Reagents. Sigma-Aldrich.