Difference between revisions of "Ethylene"

Physchim62 (talk | contribs) |

Physchim62 (talk | contribs) (→In the synthesis of fine chemicals) |

||

| Line 158: | Line 158: | ||

===In the synthesis of fine chemicals=== | ===In the synthesis of fine chemicals=== | ||

| − | Ethylene is useful in [[organic synthesis]].<ref>{{ | + | Ethylene is useful in [[organic synthesis]].<ref>{{EROS | last1 = Crimmins | first1 = M. T. | last2 = Kim-Meade | first2 = A. S. | contribution = Ethylene | doi = 10.1002/047084289}}.</ref> Representative reactions include [[Diels–Alder]] additions, [[ene reaction]], and arene alkylation. |

===Miscellaneous=== | ===Miscellaneous=== | ||

Revision as of 10:53, 24 August 2009

| Ethylene | |

|---|---|

| |

| |

| |

| IUPAC name | Ethene |

| Identifiers | |

| InChI | InChI=1/C2H4/c1-2/h1-2H2 |

| InChIKey | LFQSCWFLJHTTHZ-UHFFFAOYAB |

| Standard InChI | InChI=1S/C2H6O/c1-2-3/h3H,2H2,1H3 |

| Standard InChIKey | LFQSCWFLJHTTHZ-UHFFFAOYSA-N |

| CAS number | [] |

| EC number | |

| ChemSpider | |

| SMILES | |

| Properties[1] | |

| Chemical formula | C2H4 |

| Molar mass | 28.053 g/mol |

| Appearance | colourless gas |

| Density | 1.178 kg/m3 at 15 °C, gas |

| Melting point |

−169.2 °C (104.0 K, −272.6 °F) |

| Boiling point |

−103.7 °C (169.5 K, −154.7 °F) |

| Critical point | 282.4 K, 5.04 MPa |

| Solubility in water | 3.5 mg/100 ml (17 °C) |

| Acidity (pKa) | 44 |

| Structure | |

| Molecular geometry | D2h |

| Dipole moment | zero |

| Thermochemistry | |

| Std enthalpy of formation ΔfH |

+52.47 kJ/mol |

| Standard molar entropy S |

219.32 J K−1 mol−1 |

| Hazards[2][3] | |

| Material safety data sheet (MSDS) | ICSC |

| EU index number | 601-010-00-3 |

| GHS pictograms |

|

| GHS signal word | DANGER |

| GHS hazard statements | H220, H336 |

| Flash point | flammable gas |

| Autoignition temp. | 490 ºC (914 ºF) |

| Explosive limits | 2.7–36.0% |

| Related compounds | |

| Other alkenes | propylene |

| Other compounds | Ethane Acetylene |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) | |

Ethylene (IUPAC name: ethene) is the chemical compound with the formula C2H4. It is the simplest alkene. Because it contains a carbon-carbon double bond, ethylene is called an unsaturated hydrocarbon or an olefin. It is extremely important in industry and also has a role in biology as a hormone.[4] Ethylene is the most produced organic compound in the world; global production of ethylene exceeded 107 million tonnes in 2005.[5] To meet the ever increasing demand for ethylene, sharp increases in production facilities have been added globally, particularly in the Gulf countries. Currently the world's largest plant is situated in Asalouyeh, Iran. Jam Petrochemical Plant came online in 2008, with an annual production capacity of 1,321,000 tons, which is to be increased to 4.2 million in few years.[6]

Contents

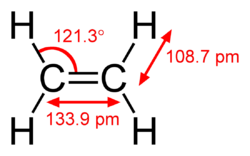

Structure

This hydrocarbon has four hydrogen atoms bound to a pair of carbon atoms that are connected by a double bond. All six atoms that comprise ethylene are coplanar. The H–C–H angle is 119°, close to the 120° for ideal sp2 hybridized carbon. The molecule is also relatively rigid: rotation about the C–C bond is a high energy process that requires breaking the π-bond, while retaining the σ-bond between the carbon atoms.

The double bond is a region of high electron density, and most reactions occur at this double bond position.

History

From 1795 on, ethylene was referred as the olefiant gas (oil-making gas), because it combined with chlorine to produce the Dutch oil (1,2-dichloroethane). Ethylene was first synthesized in 1795 by a collaboration of four Dutch chemists.

In the mid-19th century, the suffix -ene (an Ancient Greek root added to the end of female names meaning "daughter of") was widely used to refer to a molecule or part thereof that contained one fewer hydrogen atoms than the molecule being modified. Thus, ethylene (C2H4) was the "daughter of ethyl" (C2H5). The name ethylene was used in this sense as early as 1852.

In 1866, the German chemist August Wilhelm von Hofmann proposed a system of hydrocarbon nomenclature in which the suffixes -ane, -ene, -ine, -one, and -une were used to denote the hydrocarbons with 0, 2, 4, 6, and 8 fewer hydrogens than their parent alkane.[7] In this system, ethylene became ethene. Hofmann's system eventually became the basis for the Geneva nomenclature approved by the International Congress of Chemists in 1892, which remains at the core of the IUPAC nomenclature. However, by that time, the name ethylene was deeply entrenched, and it remains in wide use today, especially in the chemical industry.

The 1979 IUPAC nomenclature rules made an exception for retaining the non-systematic name ethylene[8], however, this decision was reversed in the 1993 rules[9] so the correct name is now ethene.

Uses

Approximately 80% of ethylene used in the United States and Europe is used to create ethylene oxide, ethylene dichloride, and polyethylene.[10] In smaller quantities, ethylene is used as an anesthetic agent (in an 85% ethylene/15% oxygen ratio), to hasten fruit ripening, as well as a welding gas.[10][11]

Polyethylenes of various density and melt flow account for more than 50% of world ethylene demand. The primary use of polyethylene is in film applications for packaging, carrier bags and trash liners. Other applications include injection moulding, pipe extrusion, wire and cable sheathing and insulation, as well as extrusion coating of paper and cardboard.

Ethylene derivatives include: ethylene oxide, styrene monomer (via ethyl benzene) and linear higher olefins.[10]

Ethylene oxide is a key raw material in the production of surfactants and detergents. It is also used to manufacture ethylene glycol (widely used as an automotive antifreeze), higher molecular weight glycols, and glycol ethers.

Styrene monomer is used principally in polystyrene for packaging and insulation, as well as in styrene butadiene rubber for tires and footwear.

Linear higher olefins are used as base materials for the manufacture of detergents, plasticisers, synthetic lubricants and additives, but also as co-monomers in the production of polyethylenes. [10]

Ethylene is a key component in Levinstein sulfur mustard, a chemical weapon agent.

Production

Ethylene is produced in the petrochemical industry by steam cracking. In this process, gaseous or light liquid hydrocarbons are heated to 750–950 °C, inducing numerous free radical reactions followed by immediate quench to freeze the reactions. This process converts large hydrocarbons into smaller ones and introduces unsaturation. Ethylene is separated from the resulting complex mixture by repeated compression and distillation. In a related process used in oil refineries, high molecular weight hydrocarbons are cracked over zeolite catalysts. Heavier feedstocks, such as naphtha and gas oils require at least two "quench towers" downstream of the cracking furnaces to recirculate pyrolysis-derived gasoline and process water. When cracking a mixture of ethane and propane, only one water quench tower is required.[12]

The areas of an ethylene plant are:

- steam cracking furnaces;

- primary and secondary heat recovery with quench;

- a dilution steam recycle system between the furnaces and the quench system;

- primary compression of the cracked gas (3 stages of compression);

- hydrogen sulfide and carbon dioxide removal (acid gas removal);

- secondary compression (1 or 2 stages);

- drying of the cracked gas;

- cryogenic treatment;

- all of the cold cracked gas stream goes to the demethanizer tower. The overhead stream from the demethanizer tower consists of all the hydrogen and methane that was in the cracked gas stream. Different methods of cryogenically treating this overhead stream results in the separation of the hydrogen and the methane. This usually involves liquid methane at a temperature around −100 ºC (−250 °F). Complete recovery of all the methane is critical to the economical operation of an ethylene plant. Often one or two Turboexpanders are used for Methane recovery from the demethanizer overhead stream.

- the bottom stream from the demethanizer tower goes to the deethanizer tower. The overhead stream from the deethanizer tower consists of all the C2s that were in the cracked gas stream. The C2s then go to a C2 splitter. The product ethylene is taken from the overhead of the tower and the ethane coming from the bottom of the splitter is recycled to the furnaces to be cracked again;

- the bottom stream from the deethanizer tower goes to the depropanizer tower. The overhead stream from the depropanizer tower consists of all the C3s that were in the cracked gas stream. Prior to sending the C3s to the C3 splitter this stream is hydrogenated in order to react out the methylacetylene and propadiene. Then this stream is sent to the C3 splitter. The overhead stream from the C3 splitter is product propylene and the bottom stream from the C3 splitter is propane which can be sent back to the furnaces for cracking or used as fuel.

- The bottom stream from the depropanizer tower is fed to the debutanizer tower. The overhead stream from the debutanizer is all of the C4s that was in the cracked gas stream. The bottom stream from the debutanizer consists of everything in the cracked gas stream that is C5 or heavier. This could be called a light pyrolysis gasoline.[12]

Since the production of ethylene is energy intensive, much effort has been dedicated recovering heat from the gas leaving the furnaces. Most of the energy recovered from the cracked gas is used to make high pressure (80 barg, 1200 psig) steam. This steam is in turn used to drive the turbines for compressing cracked gas, the propylene refrigeration compressor, and the ethylene refrigeration compressor. An ethylene plant, once running, does not need to import any steam to drive its steam turbines. A typical world scale ethylene plant (about 0.5–0.8 million tonnes of ethylene per year) uses a 30 MW (45,000 hp) cracked gas compressor, a 20 MW (30,000 hp) propylene compressor, and a 10 MW (15,000 hp) ethylene compressor.

When starting an ethylene plant it is important to start the cooling systems in the proper order. The cooling systems consist of Cooling Tower Water (CTW); propylene refrigeration with four or five different levels or stages. Each level corresponds to a particular pressure and temperature; and three or four stages of ethylene refrigeration. The CTW must be started first because the propylene system needs it to condense propylene and the ethylene refrigeration systems needs it to desuperheat high pressure ethylene. The propylene system must start next because the ethylene system needs high pressure propylene for desuperheating the high pressure ethylene stage and the low pressure propylene stage for condensing the high pressure ethylene. While the ethylene plant is running, the plant can continue to run for a time if the ethylene refrigeration compressor shuts down. However, if the propylene compressor shuts down the whole plant must be shut down immediately.[12]

Laboratory preparation

Ethylene can be conveniently produced in the laboratory by distilling absolute ethanol with an excess of concentrated sulfuric acid and washing the distillate vapor stream in an aqueous solution of sodium hydroxide to remove the sulfur dioxide contaminant.[13]

Peculiarity of spectrum

Although ethylene is a relatively simple molecule, its spectrum[14] is considered to be one of the most difficult to explain adequately from both a theoretical and practical perspective. For this reason, it is often used as a test case in computational chemistry. Of particular note is the difficulty in characterizing the ultraviolet absorption of the molecule. Interest in the subtleties and details of the ethylene spectrum can be dated back to at least the 1950s.

Chemical reactions

Ethylene is an extremely important building block in the petrochemical industry. It can undergo many types of reactions which leads to a plethora of major chemical products. A list of some major types of reactions includes, 1) polymerization, 2) oxidation, 3) halogenation and hydrohalogenation, 4) alkylation, 5) hydration, 6) oligomerization, 7) hydroformylation, and 8) a ripening agent for fruits and vegetables (see Physiological responses of plants).[12]

Additions to double bond

Like most alkenes, ethylene reacts with halogens to produce halogenated hydrocarbons 1,2-C2H4X2. It can also react with water to produce ethanol, but the rate at which this happens is very slow unless a suitable catalyst, such as phosphoric or sulfuric acid, is used. Under high pressure, and, in the presence of a catalytic metal (platinum, rhodium, nickel), hydrogen will react with ethylene to form ethane.

Ethylene is used primarily as an intermediate in the manufacture of other chemicals in the synthesis of monomers. Ethylene can be chlorinated to produce 1,2-dichloroethane (ethylene dichloride). This can be converted to vinyl chloride, the monomer precursor to plastic polyvinyl chloride, or combined with benzene to produce ethylbenzene, which is used in the manufacture of polystyrene, another important plastic.

Ethylene is more reactive than alkanes because of two reasons:

- It has a double bond, one called the π-bond(pi) and one called the σ-bond (sigma), where the π-bond is weak and the σ-bond is strong. The presence of the π-bond makes it a high energy molecule. Thus bromine water decolourises readily when it is added to ethylene.

- High electron density at the double bond makes it react readily. It is broken in an addition reaction to produce many useful products.

Polymerization

Ethylene polymerizes to produce polyethylene, also called polyethene or polythene, the world's most widely-used plastic. Major polyethylene product groups are low density polyethylene, high density polyethylene, polyethylene copolymers, as well as ethylene-propylene co- & terpolymers.[12]

- See also: Ziegler-Natta catalyst

Oxidation

Ethylene is oxidized to produce ethylene oxide, which is hydrolysed to ethylene glycol. It is also a precursor to vinyl acetate.

Ethylene undergoes oxidation by palladium to give acetaldehyde. This conversion was at one time a major industrial process.[15] The process proceeds via the initial complexation of ethylene to a Pd(II) center.

Major intermediates of the oxidation of Ethylene are ethylene oxide, acetaldehyde, vinyl acetate and ethylene glycol. The list of products made from these intermediates is long. Some of them are: polyesters, polyurethane, morpholine, ethanolamines, aspirin and glycol ethers.[12]

Halogenation and hydrohalogenation

Major intermediates from the halogenation and hydrohalogenation of ethylene include: ethylene dichloride, ethyl chloride and ethylene dibromide. Some products in this group are: polyvinyl chloride, trichloroethylene, perchloroethylene, methyl chloroform, polyvinylidiene chloride and copolymers, and ethyl bromide.[12]

Alkylation

Major chemical intermediates from the alkylation of ethylene include: ethylbenzene, ethyl toluene, ethyl anilines, 1,4-hexadiene and aluminium alkyls. Products of these intermediates include polystyrene, unsaturated polyesters and ethylene-propylene terpolymers.[12]

Hydration

Ethanol is the primary intermediate of the hydration of ethylene. Important products from ethanol are: ethylamines, acetaldehyde, and ethyl acetate.[12]

Oligomerization

The primary products of the Oligomerization of ethylene are alpha-olefins and linear primary alcohols. These are used as plasticizers and surfactants.[12]

Oxo-reaction

The hydroformylation (Oxo-reaction) of ethylene results in propionaldehyde with its primary products of propionic acid and n-propyl alcohol.[12]

In the synthesis of fine chemicals

Ethylene is useful in organic synthesis.[16] Representative reactions include Diels–Alder additions, ene reaction, and arene alkylation.

Miscellaneous

Production of ethylene in mineral oil-filled transformers is a key indicator of severe localized overheating (>750 °C).[17]

Ethylene as a plant hormone

Template:Cleanup-section Ethylene acts physiologically as a hormone in plants.[18][19] It exists as a gas and acts at trace levels throughout the life of the plant by stimulating or regulating the ripening of fruit, the opening of flowers, and the abscission (or shedding) of leaves. Its biosynthesis starts from methionine with 1-aminocyclopropane-1-carboxylic acid (ACC) as a key intermediate.

History of ethylene in plant biology

Ethylene has been used in practice since the ancient Egyptians, who would gash figs in order to stimulate ripening (wounding stimulates ethylene production by plant tissues). The ancient Chinese would burn incense in closed rooms to enhance the ripening of pears. In 1864, it was discovered that gas leaks from street lights led to stunting of growth, twisting of plants, and abnormal thickening of stems.[20] In 1901, a Russian scientist named Dimitry Neljubow showed that the active component was ethylene.[21] Doubt discovered that ethylene stimulated abscission in 1917[22]. It wasn't until 1934 that Gane reported that plants synthesize ethylene[23]. In 1935, Crocker proposed that ethylene was the plant hormone responsible for fruit ripening as well as senescence of vegetative tissues.[24]

Ethylene biosynthesis in plants

It has been shown that ethylene is produced from essentially all parts of higher plants, including leaves, stems, roots, flowers, fruits, tubers, and seedlings.

"Ethylene production is regulated by a variety of developmental and environmental factors. During the life of the plant, ethylene production is induced during certain stages of growth such as germination, ripening of fruits, abscission of leaves, and senescence of flowers. Ethylene production can also be induced by a variety of external aspects such as mechanical wounding, environmental stresses, and certain chemicals including auxin and other regulators"[25]

The biosynsthesis of the hormone starts with conversion of the amino acid methionine to S-adenosyl-L-methionine (SAM, also called Adomet) by the enzyme Met Adenosyltransferase. SAM is then converted to 1-aminocyclopropane-1-carboxylic-acid (ACC) by the enzyme ACC synthase (ACS); the activity of ACS is the rate-limiting step in ethylene production, therefore regulation of this enzyme is key for the ethylene biosynthesis. The final step requires oxygen and involves the action of the enzyme ACC-oxidase (ACO), formerly known as the Ethylene Forming Enzyme (EFE). Ethylene biosynthesis can be induced by endogenous or exogenous ethylene. ACC synthesis increases with high levels of auxins, specially Indole Acetic Acid (IAA), and cytokinins. ACC synthase is inhibited by abscisic acid.

Ethylene perception in plants

Ethylene could be perceived by a transmembrane protein dimer complex. The first gene encoding an ethylene receptor was first cloned from Arabidopsis thaliana by Caren Chang, Elliot Meyerowitz and colleagues at the California Institute of Technology[26] and then in tomato by Jack Wilkinson, Harry Klee and colleagues at the Monsanto Company[27]. Ethylene receptors are encoded by multiple genes in the Arabidopsis and tomato genomes. The gene family is comprised of five receptors in Arabidopsis and at least six in tomato, most of which have been shown to bind ethylene. DNA sequences for ethylene receptors have also been identified in many other plant species and an ethylene binding protein has even been identified in Cyanobacteria[28]

Environmental and biological triggers of ethylene

Environmental cues can induce the biosynthesis of the plant hormone. Flooding, drought, chilling, wounding, and pathogen attack can induce ethylene formation in the plant.

In flooding, root suffers from lack of oxygen, or anoxia, which leads to the synthesis of 1-Aminocyclopropane-1-carboxylic acid (ACC). ACC is transported upwards in the plant and then oxidized in leaves. The product, the ethylene causes epinasty of the leaves.

Physiological responses of plants

Like the other plant hormones, ethylene is considered to have pleiotropic effects. This essentially means that it is thought that at least some of the effects of the hormone are unrelated. What is actually caused by the gas may depend on the tissue affected as well as environmental conditions. In the evolution of plants, ethylene would simply be a message that was coopted for unrelated uses by plants during different periods of the evolutionary development.

List of plant responses to ethylene

- Seedling triple response, thickening and shortening of hypocotyl with pronounced apical hook. This is thought to be a seedling's reaction to an obstacle in the soil such a stone, allowing it to push past the obstruction.

- In pollination, when the pollen reaches the stigma, the precursor of the ethylene, ACC, is secreted to the petal, the ACC releases ethylene with ACC oxidase.

- Stimulates leaf and flower senescence

- Stimulates senescence of mature xylem cells in preparation for plant use

- Inhibits shoot growth except in some habitually flooded plants like rice

- Induces leaf abscission

- Induces seed germination

- Induces root hair growth – increasing the efficiency of water and mineral absorption

- Induces the growth of adventitious roots during flooding

- Stimulates epinasty – leaf petiole grows out, leaf hangs down and curls into itself

- Stimulates fruit ripening

- Induces a climacteric rise in respiration in some fruit which causes a release of additional ethylene. This can be the one bad apple in a barrel spoiling the rest phenomenon.

- Affects neighboring individuals

- Affects gravistropism

- Stimulates nutational bending

- Disease/wounding resistance

- Inhibits stem growth outside of seedling stage

- Stimulates stem and cell broadening and lateral branch growth also outside of seedling stage

- Synthesis is stimulated by auxin and maybe cytokinin as well

- Ethylene levels are decreased by light

- The flooding of roots stimulates the production of ACC which travels through the xylem to the stem and leaves where it is converted to the gas

- Interference with auxin transport (with high auxin concentrations)

- Inhibits stomatal closing except in some water plants or habitually flooded ones such as some rice varieties, where the opposite occurs (conserving CO2 and O2)

- Where ethylene induces stomatal closing, it also induces stem elongation

- Induces flowering in pineapples

Commercial Issues

Ethylene shortens the shelf life of many fruits by hastening fruit ripening and floral senescence. Tomatoes, bananas and apples will ripen faster in the presence of ethylene. Bananas placed next to other fruits will produce enough ethylene to cause accelerated fruit ripening. Ethylene will shorten the shelf life of cut flowers and potted plants by accelerating floral senescence and floral abscission. Flowers and plants which are subjected to stress during shipping, handling, or storage produce ethylene causing a significant reduction in floral display. Flowers affected by ethylene include carnation, geranium, petunia, rose, and many others[29].

Ethylene can cause significant economic losses for florists, markets, suppliers, and growers. Researchers have come up with several ways to inhibit ethylene, including inhibiting ethylene synthesis and inhibiting ethylene perception. Aminoethoxyvinylglycine (AVG), Aminooxyacetic acid (AOA), and silver ions are ethylene inhibitors.[30][31] Inhibiting ethylene synthesis is less effective for reducing post-harvest losses since ethylene from other sources can still have an effect. By inhibiting ethylene perception, fruits, plants and flowers don't respond to ethylene produced endogenously or from exogenous sources. Inhibitors of ethylene perception include compounds that have a similar shape to ethylene, but do not elicit the ethylene response. One example of an ethylene perception inhibitor is 1-methylcyclopropene (1-MCP).

Commercial growers of bromeliads, including pineapple plants, use ethylene to induce flowering. Plants can be induced to flower either by treatment with the gas in a chamber, or by placing a banana peel next to the plant in an enclosed area.

Effects upon humans

Depending on the concentration, ethylene gas can cause a pleasant odor, euphoria, nausea, hyperglycemia, a variety of psychological effects, blood pressure changes, hypoxia, loss of consciousness, or death.

Symptoms

Ethylene has a pleasant sweet faint odor, and has a slightly sweet taste, and as it enhances fruit ripening, assists in the development of odour-active aroma volatiles (especially esters), which are responsible for the specific smell of each kind of flower or fruit.

In mild doses, ethylene produces states of euphoria, associated with stimulus to the pleasure centers of the human brain. Exposure at 37.5% for 15 minutes may result in marked memory disturbances. Humans exposed to as much as 50% ethylene in air, whereby the oxygen availability is decreased to 10%, experience a complete loss of consciousness and may subsequently die due to hypoxia.

Symptoms of ethylene exposure include the following.

- Mild exposure in air

- Percent of O2 saturation at 90%

- Night vision decreased

- Mild euphoria reported.

- Moderate exposure in air

- Percent of O2 saturation at 82 to 90%

- Respiratory rate has compensatory increase

- Pulse, also a compensatory increase

- Night vision is decreased further, focus is simplified

- Performance ability is somewhat reduced, mild distortion to speech, utterances increasingly ambiguous.

- General alertness level is somewhat reduced to anything but central concerns

- Symptoms may begin in those patients with pre-existing significant cardiac, pulmonary, or hematologic diseases.

- Euphoria

- High concentration in air

- Percent of O2 saturation at 64 to 82%

- Compensatory mechanisms increasingly become inadequate

- Air hunger, gasping for breath

- Fatigue, lassitude, inability to maintain balance

- Tunnel vision, out-of-body experiences

- Dizziness

- Mild to persistent headache

- Belligerence, certainty of truth

- Extreme euphoria, belief in capacities of the self enhanced

- Visual acuity is reduced, dreamlike seeing of visions

- Numbness and tingling of extremities

- Hyperventilation

- Distortions of judgement, abnormal or illogical inferences drawn

- Memory loss after event

- Increased cyanosis

- Decreased ability for escape from toxic environment

- Very high concentration in air

- Percent of O2 saturation at 60 to 70% or less

- Further deterioration in judgment and coordination may occur in 3 to 5 minutes or less

- Severe oxygen deprivation

- Loss of consciousness results when the air contains about 11% of oxygen.

- Death occurs quickly when the oxygen content falls to 8% or less.

- Very high concentrations in oxygen

- Prolonged inhalation of about 85% in oxygen is slightly toxic, resulting in a slow fall in blood pressure.

- At about 94% in oxygen, ethylene is acutely fatal.

Medical Use

Ethylene has long been in use as an inhalatory anaesthetic. When used as a surgical anaesthetic, it is always administered with oxygen with an increased risk of fire. In such cases, however, it acts as a simple, rapid anaesthetic having a quick recovery.

Historical Significance

It has been suggested that the famous Oracle at Delphi (the Pythia) went into her trance-like state as an effect of ethylene rising from ground faults.[32]

Safety

There is no evidence to indicate that prolonged exposure to low concentrations of ethylene can result in chronic effects. Prolonged exposure to high concentrations may cause permanent effects because of oxygen deprivation. Prolonged inhalation of about 85% in oxygen (a relatively high concentration) is also slightly toxic, resulting in a slow fall in blood pressure. At about 94% in oxygen, ethylene is acutely fatal.

It shows little or no carcinogenic or mutagenic properties. Although there may be moderate hyperglycemia, post operative nausea - while higher than nitrous oxide - is less than in the use of cyclopropane. During the induction and early phases, blood pressure may rise a little, but this effect may be due to patient anxiety, as blood pressure quickly returns to normal. Cardiac arrythmias are infrequent and cardio-vascular effects are benign.

References

- ↑ Ethylene, <http://biade.itrust.de/biaen/lpext.dll?f=id&id=biadb:r:012710&t=main-h.htm> (accessed 25 October 2007), GESTIS Substance Database; BGIA

- ↑ Ethylene; International Chemical Safety Card 0475; International Labour Organization: Geneva, March 1996, <http://www.inchem.org/documents/icsc/icsc/eics0475.htm>.

- ↑ Index no. 601-010-00-3 of Annex VI, Part 3, to Regulation (EC) No 1272/2008 of the European Parliament and of the Council of 16 December 2008 on classification, labelling and packaging of substances and mixtures, amending and repealing Directives 67/548/EEC and 1999/45/EC, and amending Regulation (EC) No 1907/2006. OJEU L353, 31.12.2008, pp 1–1355 at p 450.

- ↑ Wang, K.; Ecker, J. Ethylene biosynthesis and signaling networks. Plant Cell, 14 (Suppl.), S131–51. PMID 12045274

- ↑ Chem. Eng. News July 10, 2006, 59.

- ↑ , <http://www.presstv.ir/detail.aspx?id=85063§ionid=351020102>.

- ↑ Hofmann, A. W. Hofmann's Proposal for Systematic Nomenclature of the Hydrocarbons, <http://www.chem.yale.edu/~chem125/125/history99/5Valence/Nomenclature/Hofmannaeiou.html> (accessed 6 January 2007), Chemistry Department, Yale University.

- ↑ Rule A-3.1. In Nomenclature of Organic Chemistry, Sections A, B, C, D, E, F, and H; IUPAC Recommendations 1979; Pergamon: Oxford, 1979. ISBN 0-08022-369-9, <http://www.acdlabs.com/iupac/nomenclature/79/r79_53.htm#a_3__1>.

- ↑ Rule R-R-9.1. In A Guide to IUPAC Nomenclature of Organic Compounds; IUPAC Recommendations 1993; Blackwell Science: Oxford, 1993. ISBN 0-632-03488-2, <http://www.acdlabs.com/iupac/nomenclature/93/r93_684.htm>.

- ↑ 10.0 10.1 10.2 10.3 Ethylene; SIDS Initial Assessment Profile; Organization for Economic Cooperation and Development, <http://www.inchem.org/documents/sids/sids/74851.pdf>.

- ↑ Informational Bulletin; California Fresh Market Advisory Board, June 1, 1976; Vol. 12.

- ↑ 12.00 12.01 12.02 12.03 12.04 12.05 12.06 12.07 12.08 12.09 12.10 Kniel, Ludwig; Winter, Olaf; Stork, Karl Ethylene, Keystone to the Petrochemical Industry; Marcel Dekker: New York, 1980. ISBN 0-8247-6914-7.

- ↑ Cohen, Julius B. Practical Organic Chemistry; Macmillan, 1930.

- ↑ Ethylene. In NIST Chemistry WebBook; National Institute for Standards and Technology, <http://webbook.nist.gov/cgi/inchi/InChI%3D1S/C2H6O/c1-2-3/h3H,2H2,1H3>. (accessed 27 September 2006).

- ↑ Elschenbroich, C.; Salzer, A. Organometallics: A Concise Introduction, 2nd ed.; Wiley-VCH: Weinheim, 2006. ISBN 3-527-28165-7.

- ↑ Crimmins, M. T.; Kim-Meade, A. S. Ethylene. In Encyclopedia of Reagents for Organic Synthesis; Paquette, Leo A., Ed.; John Wiley: New York, 2004. DOI: 10.1002/047084289.

- ↑ Transformerworld Tutorial No. 3, <http://www.transformerworld.co.uk/dga.htm>

- ↑ Chow, B.; McCourt, P. Plant hormone receptors: perception is everything. Genes Dev. 2006, 20 (15), 1998–2008. PMID 16882977. DOI: 10.1101/gad.1432806.

- ↑ De Paepe, A.; Van der Straeten, D. Ethylene biosynthesis and signaling: an overview. Vitam. Horm. 2005, 72, 399–430. PMID 16492477. DOI: 10.1016/S0083-6729(05)72011-2.

- ↑ (Arteca, 1996; Salisbury and Ross, 1992)

- ↑ Neljubov, D. Uber die horizontale Nutation der Stengel von Pisum sativum und einiger anderen Pflanzen. Beih. Bot. Zentralbl. 1901, 10, 128–39.

- ↑ Doubt, Sarah L. The Response of Plants to Illuminating Gas. Bot. Gaz. 1917, 63 (3), 209–24. DOI: 10.1086/332006.

- ↑ Gane, R. Production of ethylene by some fruits. Nature 1934, 134, 1008.

- ↑ (Crocker, 1935)

- ↑ Yang, S. F.; Hoffman, N. E. Ethylene biosynthesis and its regulation in higher plants. Ann. Rev. Plant Physiol. 1984, 35, 155–89. DOI: 10.1146/annurev.pp.35.060184.001103.

- ↑ Chang, C.; Kwok, S. F.; Bleecker, A. B.; Meyerowitz, E. M. Arabidopsis ethylene-response gene ETR1: similarity of product to two-component regulators. Science 1993, 262, 539–44. PMID 8211181. DOI: 10.1126/science.8211181.

- ↑ Wilkinson, J. Q.; Lanahan, M. B.; Yen, H. C.; Giovannoni, J. J.; Klee, H. J. An ethylene-inducible component of signal transduction encoded by never-ripe. Science 1995, 270 (5423), 1807–1809. PMID 8525371. DOI: 10.1126/science.270.5243.1807.

- ↑ Mount, S. M.; Chang, C. Evidence for a plastid origin of plant ethylene receptor genes. Plant Physiol. 2002, 130 (1), 10–14. PMID 12226482. DOI: 10.1104/pp.005397.

- ↑ Van Doorn, W. G. Effect of ethylene on flower abscission: a survey. Ann. Bot. 2002, 89 (6), 689–93. PMID : 12102524. DOI: 10.1093/aob/mcf124.

- ↑ Cassells, A. C.; Gahan, Peter B. Dictionary of Plant Tissue Culture; Haworth Press, 2006; p 77. ISBN 1560229195.

- ↑ Constabel, Friedrich; Shyluk, Jerry P. Plant Cell and Tissue Culture; Springer, 1994; p 5. ISBN 0792324935.

- ↑ Roach, John Delphic Oracle's Lips May Have Been Loosened by Gas Vapors; National Geographic, 2001-08-14, <http://news.nationalgeographic.com/news/2001/08/0814_delphioracle.html>. (accessed 8 March 2007).

Further reading

- Chang, C.; Stadler, R. Ethylene hormone receptor action in Arabidopsis. Bioessays 2001, 23 (7), 619–27. PMID 11462215.

- Millenaar, F. F.; van Zanten, M.; Cox, M. C.; Pierik, R.; Voesenek, L. A.; Peeters, A. J. Differential petiole growth in Arabidopsis thaliana: photocontrol and hormonal regulation. New Phytol. 2009. PMID 19558423.

External links

| Public domain and freely licensed images and media can be found in the corresponding category on Wikimedia Commons. |

| Error creating thumbnail: Unable to save thumbnail to destination | |

This page was originally imported from Wikipedia, specifically this version of the article "Ethylene". Please see the history page on Wikipedia for the original authors. This WikiChem article may have been modified since it was imported. It is licensed under the Creative Commons Attribution–Share Alike 3.0 Unported license. |